The butterfly valve is used to isolate or regulate the flow of fluid within a pipe. It has a simple structure and allows for quick operation with a 90° control angle. The valve has many advantages compared to other types of valves, especially when it comes to larger sizes, as the butterfly valve is lightweight and space-saving.

Body: Stainless Steel ASTM A351 CF 8M

Shaft: Stainless Steel ASTM AA182 F316

Disc: Stainless Steel ASTM A351 CF 8M

Seat: PTFE

Temperature: -25°C up to 220°C

Tolerances: ISO 2768-M

Face to face: EN 558 Series 20

ISO 5752 Series 20

API 609 Table 1

BS 5155 Series 4

Pressure test according to standards: API 598, ISO 5208: Body: 1.5×PN Seat: 1.1×PN

Tightness test: ISO 5208, Rate A API 598

Advantages:

- The product is applicable in various fields.

- Ensures tight sealing.

- Sealing gasket made of PTFE plastic.

- The fluid does not come into contact with the shaft and body of the valve.

- Fast opening and closing process.

- No fluid accumulation inside the valve cavity.

- Compact design, easy to install.

- Two-piece valve body for easy maintenance.

- Flexible operation with various actuators (lever, gearbox, pneumatic, electric, hydraulic, etc.).

- Low operating torque.

- Design structure with minimal pressure loss.

Applications:

|

Irrigation Industrial wastewater Fire protection systems Cooling towers |

Food processing plants Paper mills Chemical industry Oil and gas industry |

Thermal power Shipbuilding industry Mining Air conditioning Metallurgy …. |

Flow coefficient (Cv): Cv = 1.16 x Kv

Where Kv is the amount of water flowing through a valve (m³/h) with a pressure differential of 1 bar at 20°C.

The flow rate will increase linearly with the valve opening, as shown in the following chart:

.png)

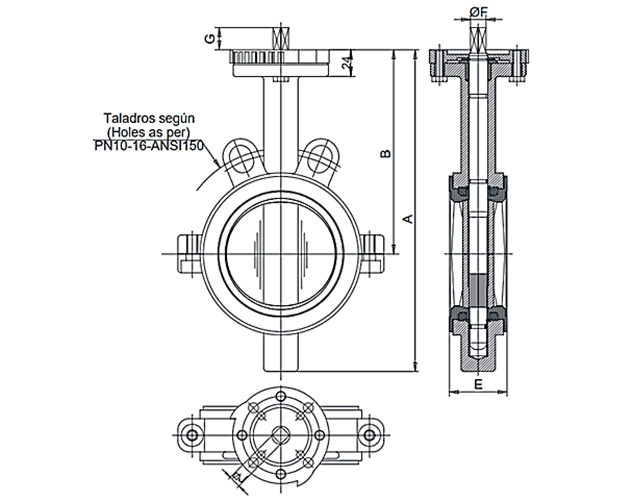

Dimension table:

| dn | A | B | E | F | G | J | ISO 5211 | WEIGHT KG |

|

| mm | in | ||||||||

| 40 | 1 1/2" | 205 | 140 | 33 | 9.8 | 14 | 8 | F05-07 | 2 |

| 50 | 2" | 226 | 156 | 43 | 9.8 | 14 | 8 | F05-07 | 3.5 |

| 65 | 2 1/2" | 242 | 161 | 46 | 12 | 16 | 9 | F05-07 | 4.5 |

| 80 | 3" | 262 | 167 | 46 | 14 | 16 | 11 | F05-17 | 5 |

| 100 | 4" | 290 | 184 | 52 | 14 | 20 | 11 | F07 | 6.5 |

| 125 | 5" | 326 | 207 | 56 | 18 | 20 | 14 | F07 | 8 |

| 150 | 6" | 348 | 215 | 56 | 18 | 20 | 14 | F07 | 9 |

| 200 | 8" | 438 | 257 | 60 | 22 | 24 | 7 | F07 | 15 |