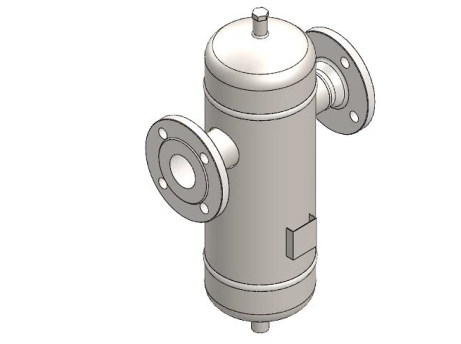

CEFI 32 Air Stream Separators are used for the removal of entrained liquid or solids from steam or air, according baffle and cyclone principle.

Series: CEFI 32

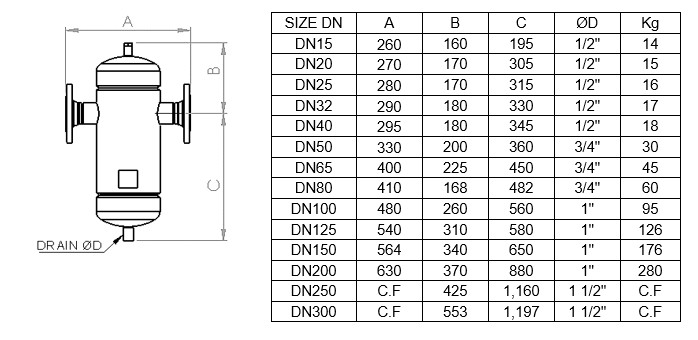

Size: DN15 to DN300

Connections: Flanged DIN, ANSI

Body Material: Carbon steel

Pressure Design: PN16, PN40

Max. Operating Temperature: Saturated Steam Temperature

Benefits of our Technology:

- Create fluid dryness

- Increase heating efficiency

- Baffle and cyclone principle.

- Separation of 99% of particles from 10 micron

- Minimum pressure drop

- Reduce the risk of water damage system

- Reduced risk of equipment oxidation for compressed air applications

Operating principle:

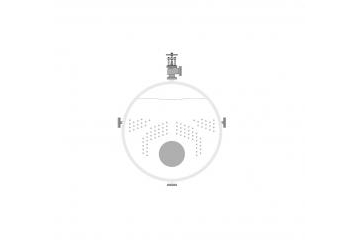

Wet steam / air flow enters the inlet of the separator where it is baffle plate and deflected in a centrifugal downward motion. The entrained moisture is separated out by reduction in velocity. Separated liquid then falls below the Vortex Containment Plate where it cannot be re-entrained. Dry steam or air then flows upward and exits through the outlet of the separator.

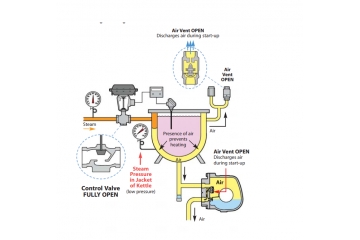

Steam separator application: Application industry

- Steam from boiler - Hospitals, hotels

- Main steam line - Food and pharmaceutical production system

- Before enter turbine - Soft drink

- Before Heat exchanger / radiator - Paper

- Before Sterilizer machine - Textile dyeing

- Before pressure regulator / control valve - Chemical factory

- Before Direct dryer machine - Oil and Gas

- Ironing system - Thermal - Petrochemical

- and more. - and more.

Application of dehumidification of compressed air/industrial gas:

- From the compressed air source

- Before entering the device

- and more.

Dimensions (mm):