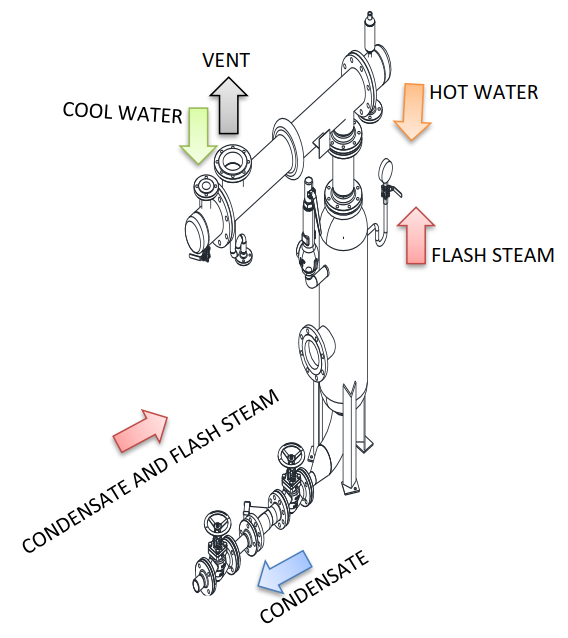

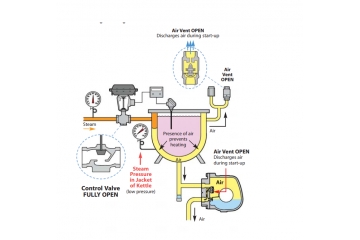

When the pressure of saturated condensate is reduced, a portion of the liquid “flashes” to low-pressure steam. Depending on the pressures up stream, the flash steam contains normally 3% to 50% of the energy content of the original condensate. Almost cases, condensate receivers the flashing steam is vented to atmosphere and its energy content lost. The SVC Steam Vent Condenser can be installed in the vent to recover this energy.

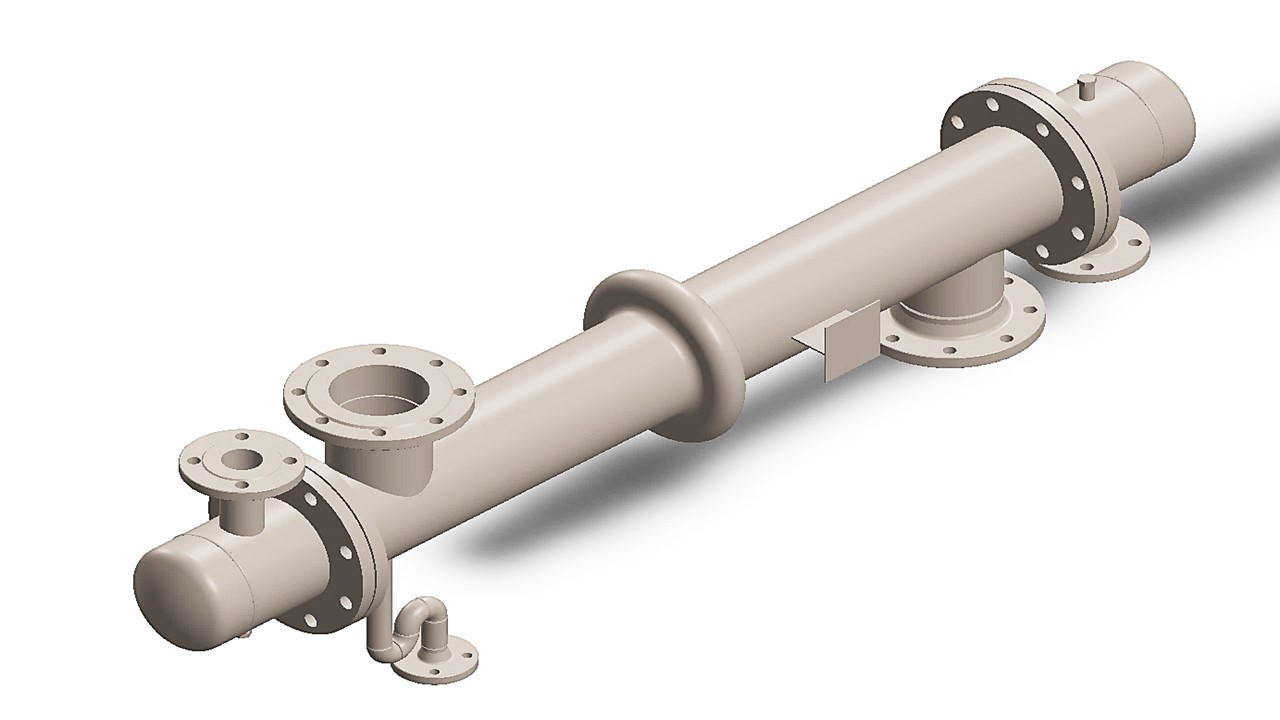

SVC Steam Vent Condenser is a heat recovery unit. It is recovery flash steam discharge from steam trap system to re-heat process fluid, increasing energy efficient use in plant and reducing heat loss to atmosphere. The SVC designed to recover the latent heat of steam by condensing that steam vapor to liquid which may then be safely diverted and recovered while minimizing equipment damage due to corrosion, otherwise energy vent to atmosphere. The SVC completed stainless steel construction, flanged connection.

Benefits of our Technology:

- Reduced CO2 + Carbon emissions.

- Increasing energy efficient use in plant.

- Energy recovery from latent heat process.

- Eliminate remaining flash steam energy loss.

- Water recovery from condensate.

- Stop moisture damage to the roofing structure.

- Water and chemical treatment savings.

- Improved cash flow.

Typical installation: