-

31/10/2020

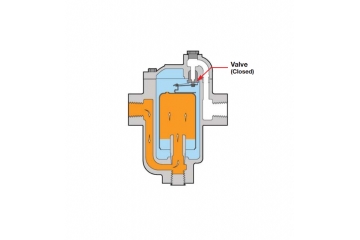

The inverted bucket within the trap will rest on the bottom of the trap body keeping the valve open and allowing condensate to be discharged (Figure A). In the top of the bucket there is a small bleed hole which allows air to escape from inside the bucket and exit through the outlet port (Figure B). When steam arrives through the inlet of the trap, it fills the inverted bucket which makes it buoyant and rise to the top of the trap, closing the valve (Figure C). As steam condenses and/or is bled through the small bleed hole in the top of the bucket, the bucket loses buoyancy which causes it to sink to the bottom of the trap. The valve then opens allowing condensate to be discharged from the system (Figure A). The bucket trap must maintain a certain amount of water (prime) in order to operate. If the trap loses its prime, the bucket will not be able to float when steam enters; keeping the valve in the open position which allows steam to escape (Figure D). Due to the balance of forces required between the incoming pressure and internal trap components, several orifice sizes are required to accommodate various differential pressure ranges. For this reason care must be used to select a trap model with an equal or higher PMO rating than the steam pressure. Discharging Condensate With condensate completely filling the trap, the bucket is in the down position with the valve open, allowing condensate to be discharged Discharging Air Small amounts of air will pass thru the bleed hole on top of the bucket and be discharged. (Note: Large amounts of air will lift the bucket and close off the trap, temporarily air locking the system.) Closed (Trapping Steam) When steam enters the trap, the inverted bucket fills with steam and floats to the surface, closing off the valve, preventing steam from escaping. Potential Failure Mode (Loss of Prime) Potential Failure Mode: Bucket traps must maintain a water prime to function properly. If the prime is lost, the bucket will remain in the down position with the valve open, and live steam will be discharged from the system.

-

20/10/2020

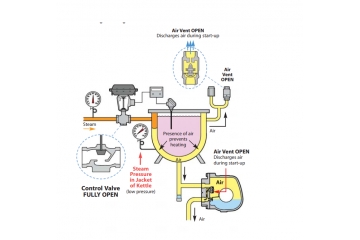

The bellows type thermostatic traps contains a fluid-filled thermal element (bellows). The operation of the bellows follows the steam saturation curve, always discharging condensate a few degrees cooler than the steam temperature. As long as steam is present, the valve will remain closed. Only when subcooled condensate or air is present will the valve open. Sub-Cool: The sub-cooling of condensate prior to discharge can have certain beneficial effects. In the majority of tracing applications, the sub-cooling of condensate is highly desirable because of the additional energy that is extracted from the Hot condensate. If the trap did not sub-cool condensate, this energy would be wasted. In Batch style process applications such as jacketed kettles, plating tanks and heating of outdoor storage tanks, the sub-cooling of condensate is generally not a factor to consider since the amount of condensate back-up requires less than 1% of the heat transfer surface area and is therefore considered negligible. Air When air, which is cooler than steam, is present, the bellows is retracted and the seat is open, allowing large quantities of air to be discharged. Condensate When condensate, which is cooler than steam, is present, the bellows retracts and the seat opens, allowing condensate to be discharged Steam When steam reaches the trap, the bellows expands, closing off the seat and preventing the steam from escaping.

-

09/10/2020

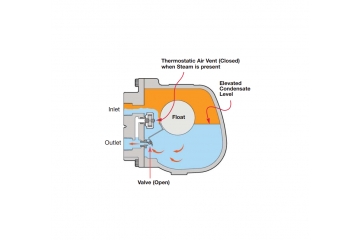

Float & Thermostatic steam traps are the most common trap type used for process applications. They use a float-operated valve mechanism to discharge condensate as it is formed, and an air vent for discharging air at start-up; both very important requirements for process applications. Venting Air Prior to the steam being turn on the piping system, heat exchanger and trap are filled with air which is much cooler than steam. The thermostatic air vent will be in the wide open position. During startup this air will be pushed through the air vent by the incoming steam into the condensate return line. Discharging Condensate When condensate enters the trap, the float lifts which opens the valve, allowing condensate to discharge. Closed (Trapping Steam) When steam is present, and no condensate is entering the trap, the valve and thermostatic air vent remain closed, trapping steam in the system.

-

02/10/2020

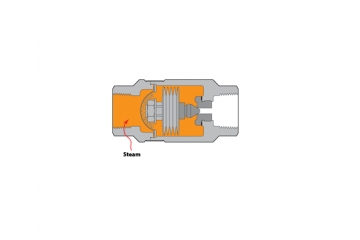

Thermodynamic Steam Trap Thermodynamic traps have only one moving part, the valve disc, which allows condensate to be discharged when present and closes tightly upon the arrival of steam. These traps have an inherently rugged design and are commonly used as drip traps on steam mains and supply lines. Their solid construction and single moving part make them resistant to waterhammer and are freeze-proof when installed vertically. Thermodynamic traps will only discharge small amounts of air and therefore are typically not used in process applications Valve Disc Open When condensate is present, trap remains in the open position allowing condensate to discharge. Steam pressure pushes the condensate thru the trap. Valve Disc Starting to Close When steam enters the trap, it creates an internal pressure above the disc that instantly forces the disc and seat to close tightly, preventing steam from escaping. Valve Disc Closed Steam pressure above the disc holds the disc closed, trapping steam in the system. Trap will remain closed until the steam above the disc condenses, due to heat loss through the cap.

Copyright © 2020 Technical TL +