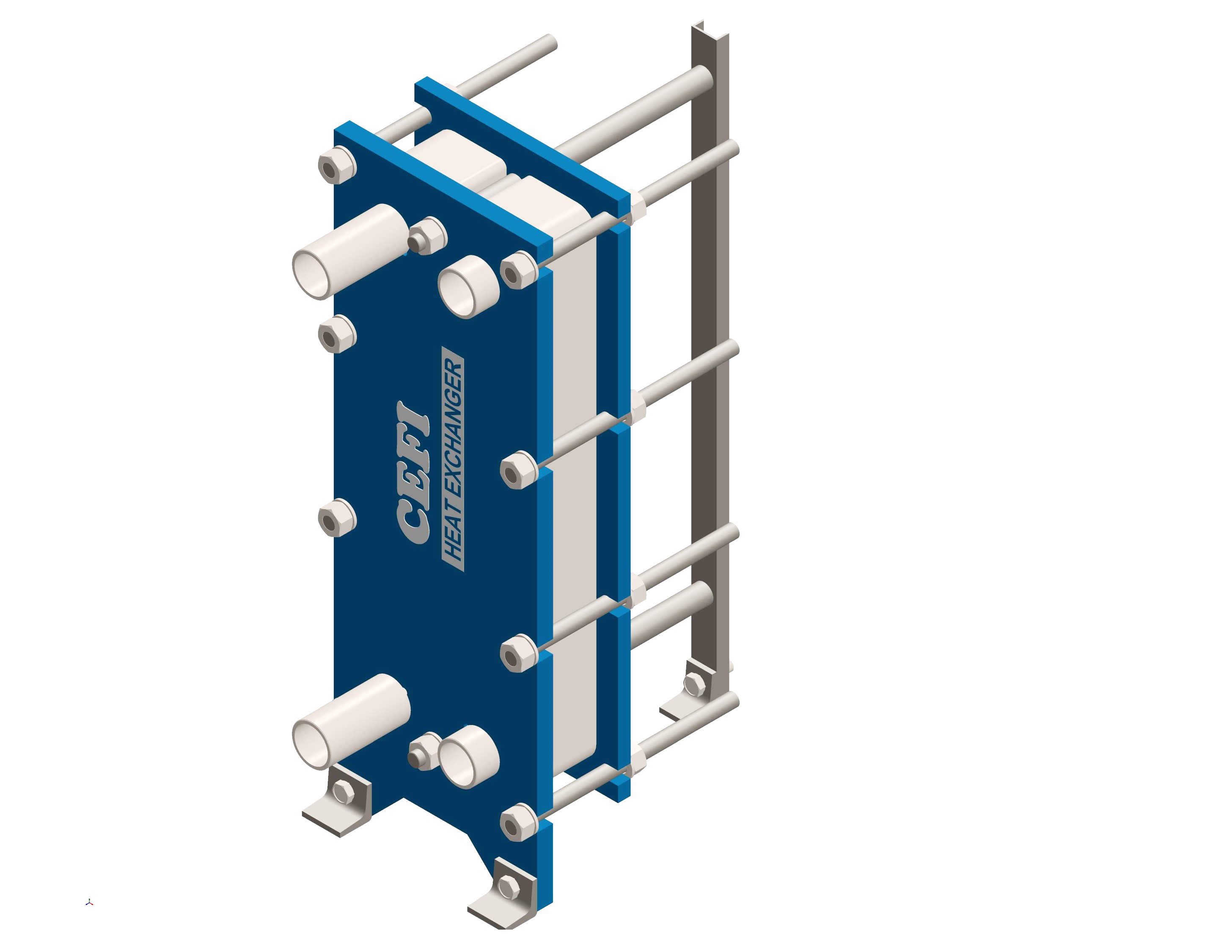

CF30 plate heat exchanger with gasket is designed with many energy transfer plates combined with sealing gaskets, applying heat energy exchange from one fluid to another with maximum efficiency. The heat exchanger meets and is widely used in many industries. Along with the advantages of high efficiency, compact, easy to disassemble, clean and sterilization.

The heat exchanger is designed, customized plates according to each application need, versatile and high thermal energy exchange efficiency, becoming the perfect solution considered for many applications.

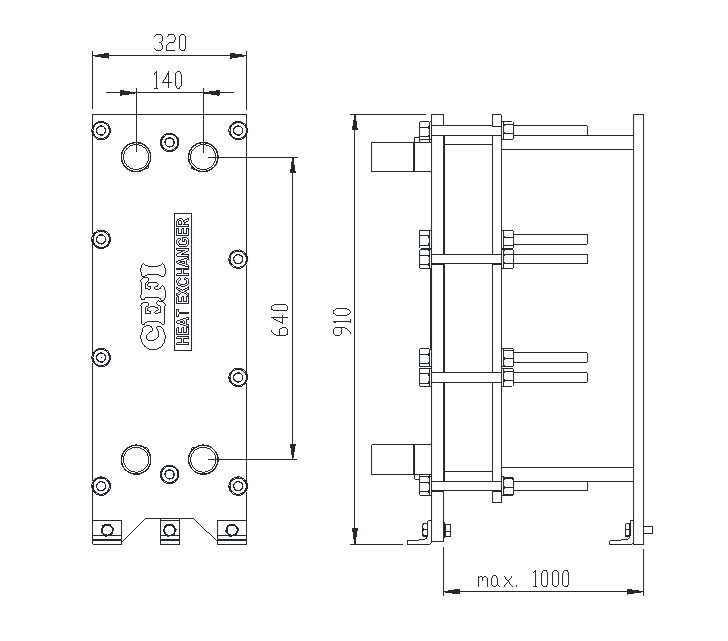

The energy exchanger plates are designed and manufactured by corrosion-resistant materials from stainless steel AISI SS304/SS316/titanium. The plates are hung, arranged on the guide rail and combined with sealing gaskets then tightened with bolts between the fixed frame and the moving frame. Creating a certain distance between the plates allows the fluid to move in the predetermined direction of the design from the inlets to the outlets.

Specifications:

Plate material in AISI SS304L/SS316L/titanium, Other materials available on request

Frame: Carbon steel painted RAL 5017

Stainless steel

Gasket material EPDM, NBR and Viton

Working pressure up to 25 bar

Operating temperature up to 180°C

Connections size from DN50

Connection type, threaded BSP, NPT, flanged, clamp, Union

Benefits of our Technology:

- Energy exchange plate is customized design with high turbulence, low fouling, continuous flow and short fluid residence time

- Variety pressing depth increasing flow efficiency and reduces the risk of clogging

- Flexible design with different plate configurations

- Easy access to heat transfer surface, ability to change configuration to suit changing process and functions by changing the number of energy transfer plates

- Design combined with sealing gasket, low risk of leakage

- Efficient energy exchange, high energy exchange coefficient for both fluid flows

- Low possibility of leakage between two fluids

- The same design frame can combine the task of transmitting energy for more than two fluids

- Only the edges of the plate are in contact with the environment, small heat energy loss

- Compact, space-saving

- Lower operating cost

- Easy installation

Typical application:

Heating system Steam condensing

Cooling system Domestic hot water heating

Heat recovery Data centers

Construction standards:

EN13445

ASME sec VIII, Div. 1

Customers sectors:

- Hospitals & Hotels - Industrial Sector

- Food Processing Plants - Commercial Laundries

- Pharmaceutical Industry - Power Plants

- Chemical Industry - Beverage Industry

- Manufacturing Industry - Textile Industry

- Oil & Gas Industry - And many more.

- Paper & Pulp Industry

Dimensions (mm):